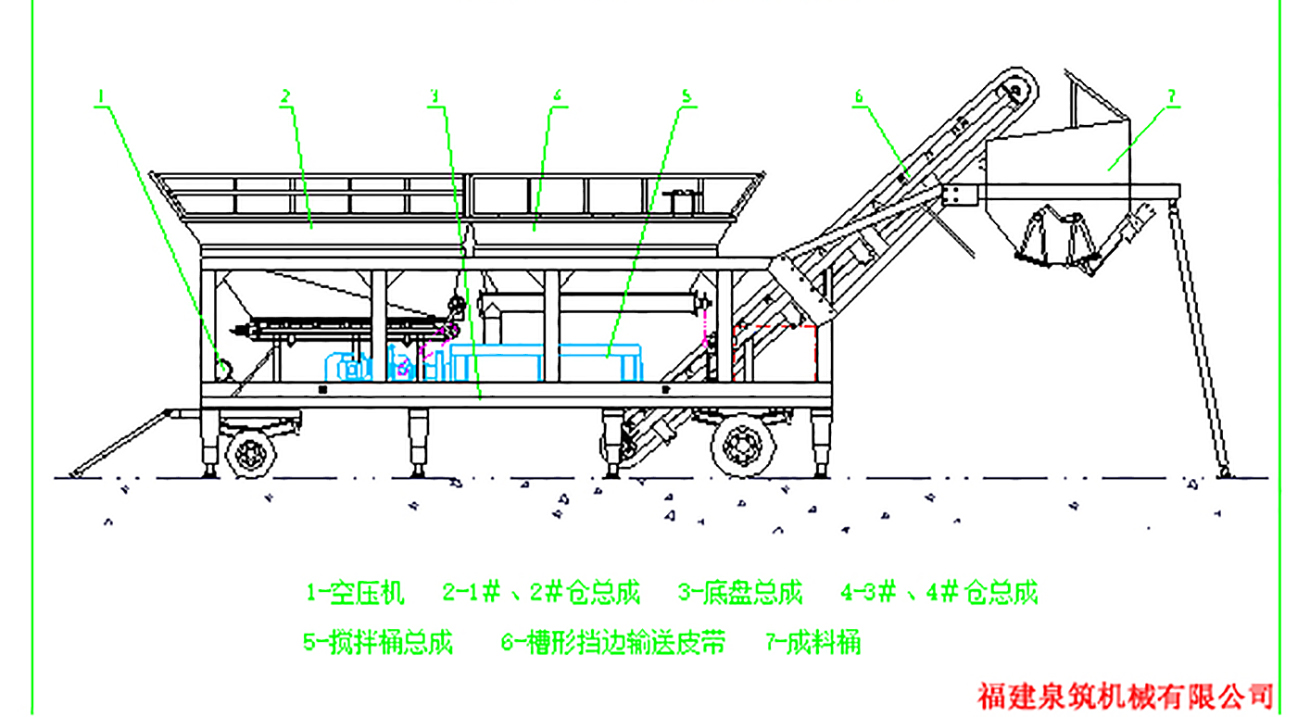

YWBS移動穩(wěn)定土攪拌站Mobile stabilized soil mixing plant

概述:移動式穩(wěn)定土廠拌設(shè)備,主要用于高等級公路、城市道路、機場、港口等工程的基層穩(wěn)定土層的連續(xù)拌和作業(yè),也可用于灰土層的生產(chǎn)及可壓實混凝土的拌和作業(yè)。

特點:在一個拖掛單元上完成穩(wěn)定土拌和的所有功能,可對多種級配的集料進(jìn)行計量、混料、攪拌、提升、成料品稱量等操作,實現(xiàn)自動連續(xù)生產(chǎn)。整機功能極佳,一拉即走,一停就用,混合拌料均勻,計量準(zhǔn)確可靠,操作簡單方便。

設(shè)備構(gòu)成:

1、骨料配料供給系統(tǒng):骨料倉、出料皮帶機;

2、粉料供給系統(tǒng):粉料倉、螺旋輸送機、斗式提升機;

3、供水系統(tǒng):水箱、水泵、流量計、執(zhí)行機構(gòu)、閥門、噴水器;

4、攪拌裝置:電機、減速機、雙臥軸攪拌機;

5、儲料裝置:槽形皮帶機、成品倉、氣缸、三聯(lián)件、電磁閥、空壓機;

6、控制室:PLC、控制柜、配電盤、操作臺、空調(diào)。

工藝流程:

1、所需骨料分別用裝載機裝入各個料斗,根據(jù)配比調(diào)整好料倉開門高度,開啟骨料輸送電機,把骨料送入攪拌裝置;

2、所需粉料由粉倉經(jīng)螺旋輸送機送至攪拌機內(nèi),可根據(jù)配比量調(diào)整螺旋輸送機轉(zhuǎn)速來控制出料量的大小;

3、攪拌用水由水泵經(jīng)過調(diào)節(jié)閥門及管路按工程所需水量送至加水器噴頭,均勻地噴灑在攪拌裝置內(nèi);

4、進(jìn)入攪拌機的物料在臥置機內(nèi)相互反轉(zhuǎn)的兩根攪拌軸上雙道螺旋漿片的攪拌下,受到漿片周向、徑向、軸向力的作用,使物料產(chǎn)生擠壓磨擦、剪切、對流,從而進(jìn)行劇烈的強制攪合,并向出料口推移;

5、當(dāng)物料到達(dá)機內(nèi)出料口時,各種物料已相互得到均勻的拌合,并具有了壓實需要的含水量,此后均勻的物料由出料口落到槽形皮帶機上,由該皮帶機輸送到成料倉內(nèi),等待運料車到來后,由氣缸控制的斗門開啟,裝車后斗門關(guān)閉,成品料運往施工現(xiàn)場。

Overview: Mobile stabilized soil plant mixing equipment is mainly used for the continuous mixing operation of the basic stable soil layer of high-grade highways, urban roads, airports, ports and other projects, and can also be used for the production of gray soil layer and the mixing operation of compacted concrete.

Features: All the functions of stabilizing soil mixing can be completed on a single towing unit, which can be used for measuring, mixing, stirring, lifting, weighing and other operations of various graded aggregates to achieve automatic continuous production. The whole machine has excellent function, one pull is gone, one stop is used, the mixture is uniform, the measurement is accurate and reliable, the operation is simple and convenient.

Equipment composition:

1. Aggregate batching supply system: bone bin, discharging belt machine;

2, powder supply system: powder silo, screw conveyor, bucket elevator;

3, water supply system: water tank, pump, flow meter, actuator, valve, sprinkler;

4, mixing device: motor, reducer, double horizontal shaft mixer;

5, storage device: trough belt machine, finished product bin, cylinder, triplet, solenoid valve, air compressor;

6, control room: PLC, control cabinet, switchboard, operation station, air conditioning.

Process flow:

1, the required aggregate is loaded into each hopper with a loader, adjust the height of the bin door according to the ratio, open the aggregate conveying motor, and send the aggregate into the mixing device;

2. The required powder is sent to the mixer by the screw conveyor from the powder bin, and the speed of the screw conveyor can be adjusted according to the proportion to control the size of the output volume;

3. Mixing water is sent to the nozzle of the water feeder by the pump through the regulating valve and pipeline according to the water requirement of the project, and evenly sprayed in the mixing device;

4. The material entering the mixer is stirred by the double spiral blade on the two mixing shafts that reverse each other in the horizontal machine, and is subjected to the action of the circumferential, radial and axial forces of the blade, which causes the material to produce extrusion friction, shear and convection, so as to carry out violent forced mixing and push towards the discharge port;

5, when the material arrives at the discharge port of the machine, all kinds of materials have been evenly mixed with each other, and have the water content required for compaction, then the uniform material falls from the discharge port to the trough belt machine, transported by the belt machine to the hopper, waiting for the arrival of the material truck, the hopper door controlled by the cylinder is opened, the hopper door is closed after loading, and the finished material is transported to the construction site.

閩公網(wǎng)安備 35058302350901號

閩公網(wǎng)安備 35058302350901號